Khớp nối bánh răng Kop-Flex® | Gear Couplings Kop-Flex®

Khớp nối bánh răng Kop-Flex® là một thiết bị cơ khí nhằm truyền mô-men xoắn giữa hai trục không thẳng hàng. Khớp nối thường bao gồm hai khớp linh hoạt, một khớp cố định vào mỗi trục. Các khớp này thường được liên kết bởi một trục thứ ba gọi là trục chính.

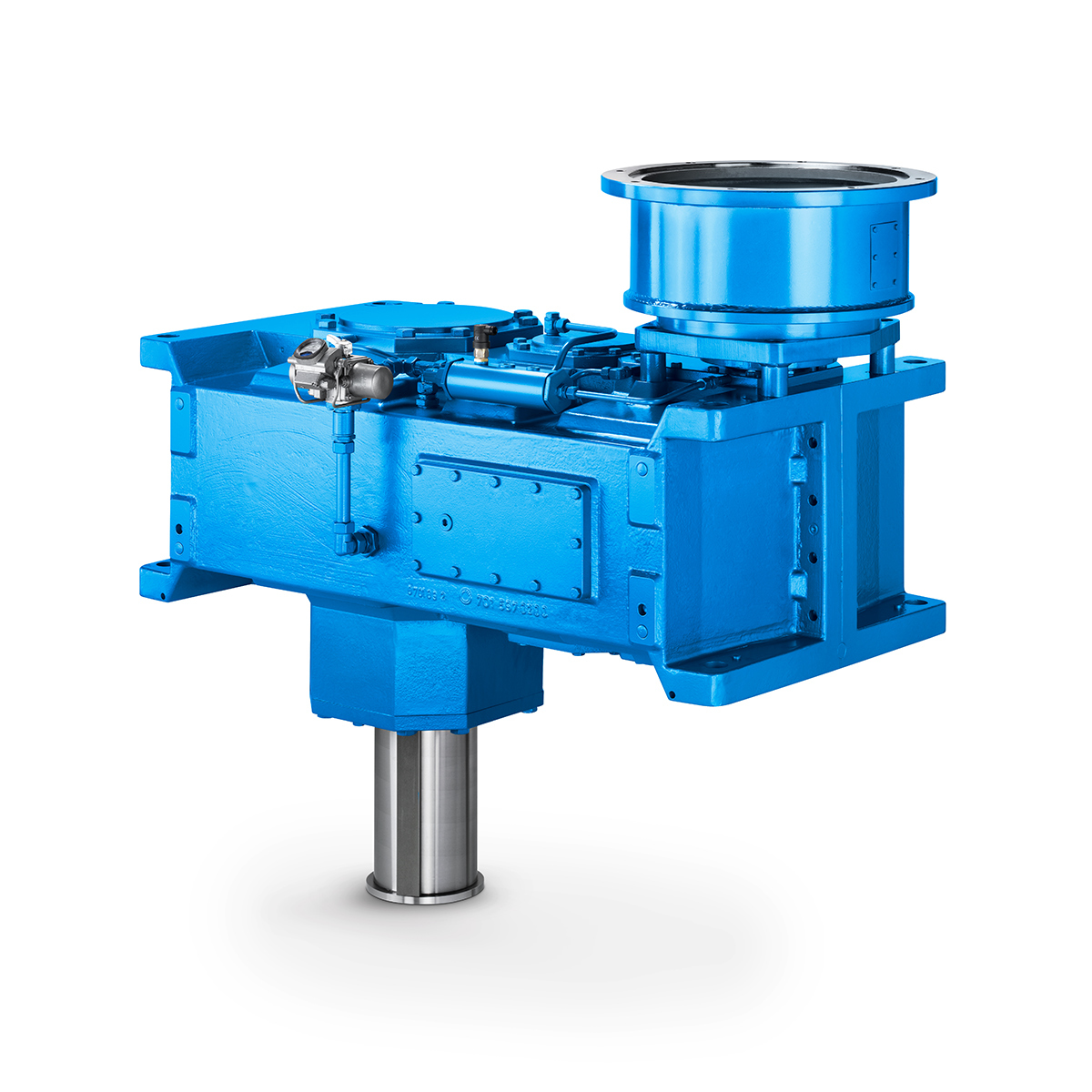

- SERIES H | Series H Gear Couplings

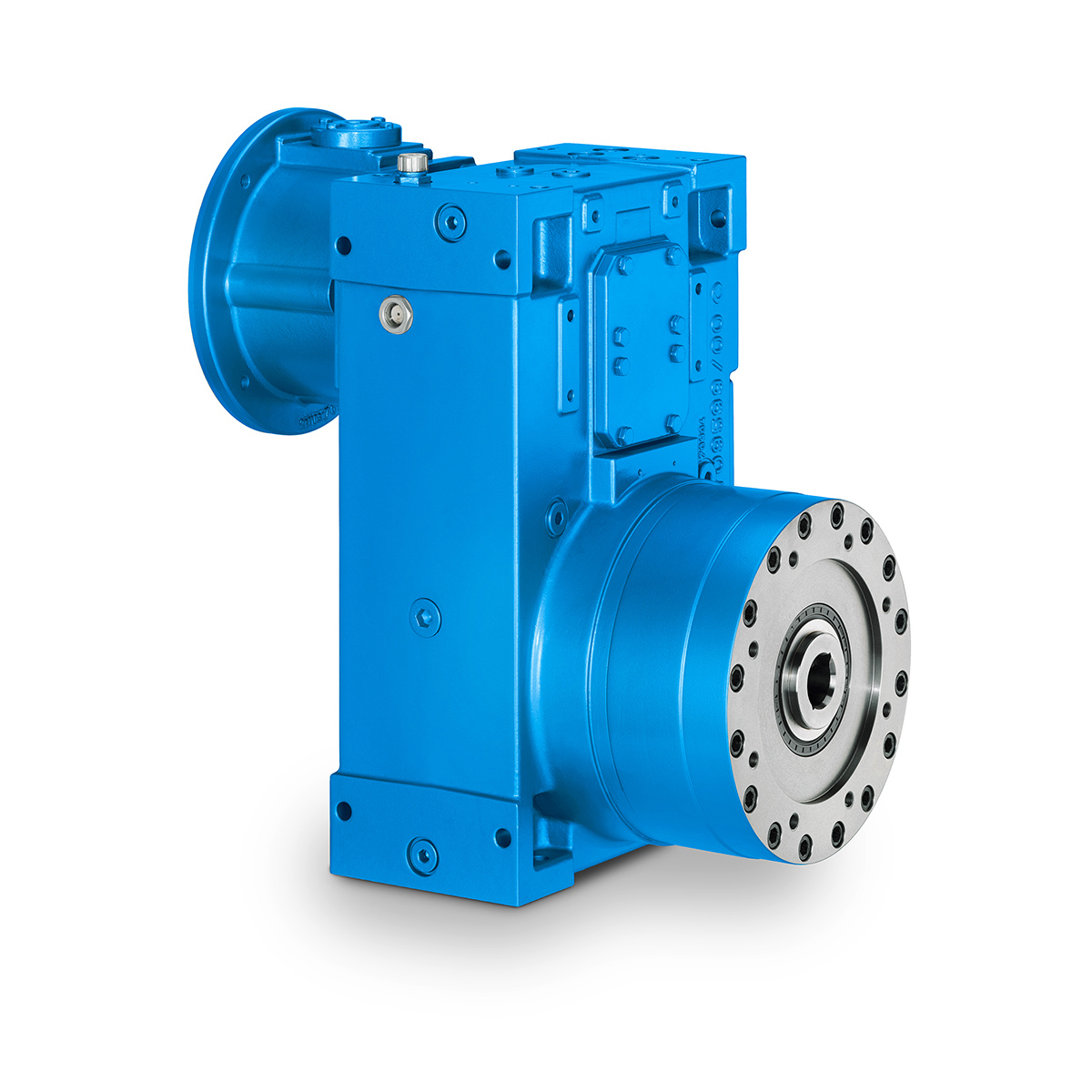

- FAST’S® COUPLING | FAST’S® Gear Couplings

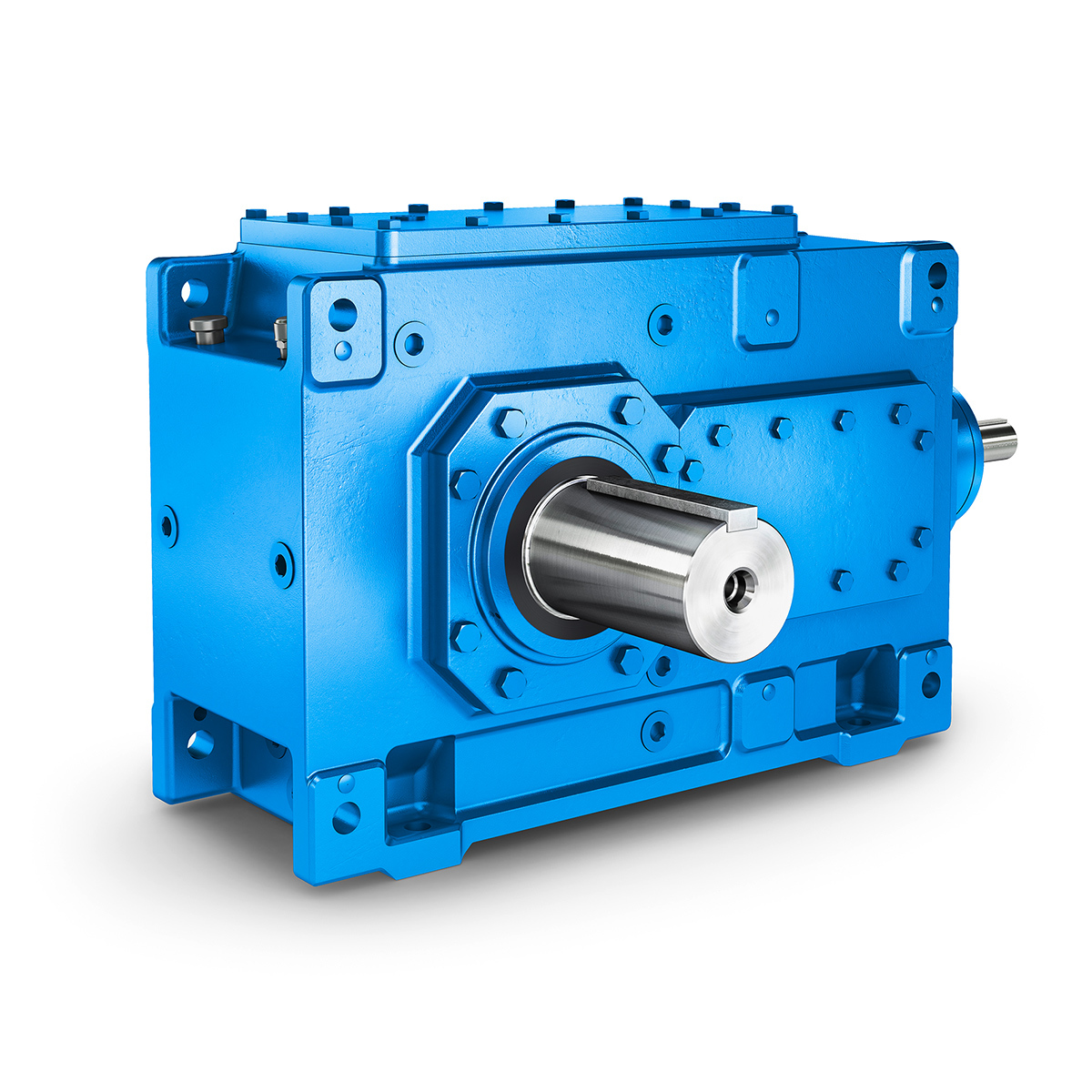

- WALDRON® COUPLING | WALDRON® Gear Couplings

Nội dung chi tiết

Khớp nối bánh răng Kop-Flex® là một thiết bị cơ khí nhằm truyền mô-men xoắn giữa hai trục không thẳng hàng. Khớp nối thường bao gồm hai khớp linh hoạt, một khớp cố định vào mỗi trục. Các khớp này thường được liên kết bởi một trục thứ ba gọi là trục chính.

Khớp nối bánh răng Kop-Flex® bao gồm:

| SERIES H | FAST’S® COUPLING | WALDRON® COUPLING |

| Khả năng điều chỉnh sai cao hơn

Kích thước 1-7 bù cho độ lệch góc tĩnh lên tới ±1 1/2° trên mỗi lưới bánh răng. Giảm thiểu độ lệch khi vận hành sẽ tối đa hóa tuổi thọ của khớp nối. Tham khảo Hướng dẫn lắp đặt và căn chỉnh để biết các khuyến nghị căn chỉnh. Khả năng khoan lớn hơn cho phép lựa chọn kích thước tiết kiệm nhất cho trục lên tới 10 5/8″. Xếp hạng mô-men xoắn cao hơn do đường kính bước răng lớn hơn so với các khớp nối khác. Tính linh hoạt trong Series H đó có thể được hoán đổi bằng khớp nối một nửa với các thiết kế khớp nối cạnh tranh. 1 Răng mặt cong 1/2° là đặc điểm chính của khớp nối Series H, kích thước 1-7. Răng trung tâm có vương miện là dạng răng liên quan có độ sâu đầy đủ 20° với độ cong ở sườn, đầu và chân răng. Khi được sử dụng với các răng ống bọc mặt thẳng, các trục mặt cong 1 1/2° này giúp tăng khả năng điều chỉnh trục lệch

|

Khớp nối bánh răng FAST’S có hai dòng sản phẩm cơ bản:

1. Khớp nối FAST’S dành cho các ứng dụng từ trung bình đến nặng

· Kích thước 1 1/2 đến 7 với vòng cuối tích hợp. · Kích thước từ 8 đến 30 với vòng cuối bắt vít.

2. Khớp nối FAST’S Model B dành cho các ứng dụng tải nhẹ đến trung bình · Khớp nối Model B không thể thay thế được bằng khớp nối FAST’S® tiêu chuẩn. · Kích thước 1 1/2 đến 3 1/2 với vòng đầu tích hợp.

|

· IMPROVED SOFT SEAL cung cấp khả năng bịt kín vượt trội trong các điều kiện không thẳng hàng. · UNIQUE TOOTH FORM sử dụng góc áp suất 40°, phân phối tải trọng trên diện tích lớn hơn so với khớp nối sử dụng góc áp suất 20°. · FULL TOOTH ENGAGEMENT làm giảm sự mài mòn không đều trên răng, mang lại tuổi thọ cao hơn cộng với hiệu suất được cải thiện. · QUALITY EXPOSED FASTENERS bao gồm bu lông SAE Cấp 5 với đai ốc lục giác và vòng đệm khóa. Cài đặt rất đơn giản, không cần công cụ đặc biệt. Bu lông bọc tùy chọn. · CLEAR RUST INHIBITIVE AND CORROSION RESISTANT FINISH bảo vệ khớp nối trong môi trường công nghiệp thông thường. · AVAILABLE OFF-THE-SHELF trong các thiết bị khoan lại có khả năng khoan lớn hoặc khoan hoàn thiện nguyên gốc. · OPTIONAL PILOT RINGS cung cấp thanh ghi tích cực giữa các nửa giống hệt nhau. Loại bỏ yêu cầu lắp ráp có chọn lọc ở tay áo nam, nữ. · INTERCHANGEABLE bằng khớp nối một nửa với các thiết kế khớp nối cạnh tranh. · HIGHER MISALIGNMENT CAPABILITY kích thước 1-7 bù đắp cho độ lệch góc tĩnh lên tới ±1 1/2° trên mỗi lưới bánh răng. |

| Series H Gear Couplings | FAST’S® Gear Couplings | WALDRON® Gear Couplings |

| Các khớp nối Series H có Kích thước 8 đến 30 được thiết kế để có độ lệch ±1/2° trên mỗi khớp nối nửa uốn, để bù cho độ lệch giữa các trục trong khớp nối uốn hoàn toàn. Các khớp nối Series H có thể được cung cấp ở dạng linh hoạt hoàn toàn, linh hoạt-cứng, trục nổi và miếng đệm cũng như các thiết kế tùy chỉnh. Chỉ có mặt bích bu lông lộ ra mới có kích thước từ 8 đến 30.

Dạng răng sơ khai không liên quan, mặt thẳng được sử dụng trong khớp nối Series H, kích thước từ 8 đến 30. Dạng răng này phân phối áp lực tiếp xúc trên toàn bộ chiều dài của răng trung tâm, để phát triển tốt nhất màng bôi trơn cần thiết, giảm thiểu mài mòn và giãn răng tuổi thọ của khớp nối trong nhiều năm hoạt động. Các vòng cuối có thể tháo rời để dễ lắp ráp và cho phép kiểm tra các bộ bánh răng. Vòng đệm chữ O Buna-N được kết hợp để giúp loại bỏ chất gây ô nhiễm và giữ lại chất bôi trơn.

|

Thiết kế FAST’S®, với vòng đầu hoàn toàn bằng kim loại có tuổi thọ cao, mang lại khả năng bôi trơn lớn hơn tới 300%. Điều này có nghĩa là khoảng thời gian dài hơn giữa các lần tái bôi trơn có thể được lên lịch.

Vòng cuối hoàn toàn bằng kim loại, được sử dụng riêng trong khớp nối FAST’S®, loại bỏ sự cần thiết của bất kỳ loại vòng đệm bôi trơn dễ hỏng nào (vòng chữ o, vòng đệm môi, miếng đệm nút chai, v.v.). Vòng cuối không chỉ cung cấp đập mà chất bôi trơn phải chảy qua để thoát ra ngoài mà còn điều khiển ống bọc đối với trục trong quá trình khởi động và tắt máy. Nó còn giúp loại bỏ tình trạng rời ra một phần răng dẫn đến tình trạng quá tải răng bằng cách cung cấp các răng bọc nằm ngang với thành trong của vòng cuối. |

· FULL ENGAGEMENT TEETH

Khớp nối bánh răng WALDRON® đã được thiết kế với sự ăn khớp toàn bộ răng với kết quả vốn có là tuổi thọ dài hơn và hiệu suất được cải thiện. · OPTIONAL PILOT RINGS Khớp nối WALDRON® tiêu chuẩn bao gồm hai nửa khớp nối giống hệt nhau. Các vòng thí điểm bằng thép chính xác tùy chọn có sẵn khi cần định tâm chính xác hơn hai ống bọc. · HIGH MISALIGNMENT SEAL Khớp nối bánh răng cạnh tranh kết hợp vòng đệm chữ O. Để phù hợp với khả năng điều chỉnh độ lệch cao hiện nay, vòng chữ O này phải vừa với một rãnh lớn hơn vòng. Khớp nối WALDRON® sử dụng vòng đệm có độ lệch thực sự cao để bịt kín đáng kể trong các điều kiện không thẳng hàng. · WALDRON® POWERLIGN Thiết kế không mặt bích này truyền mô-men xoắn giống hệt như Khớp nối WALDRON® tiêu chuẩn. Tuy nhiên, có đường kính bên ngoài nhỏ hơn, nó nhỏ gọn hơn, nhẹ hơn và có thể chạy ở tốc độ cao hơn. Sự thay thế này có thể được chọn cho các ứng dụng có không gian hạn chế. |

Mỗi dòng của Khớp nối bánh răng Kop-Flex® được thiết kế phù hợp cho từng ứng dụng riêng biệt. Liên hệ Regal hoặc Hotline: +84 938 438 598 để được tư vấn cụ thể nhé.